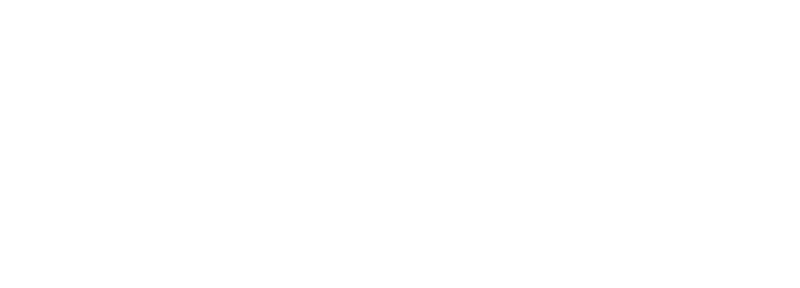

Volute Dewatering Press

ADVANTAGES

- Eliminates thickening and storage tanks

- Delivers 24-hour unattended operation

- Reduces running costs

- Handles feed sludges from <0.2% to >4%

- Offers less noise, less odor

- Designed for fast and easy installation

Description

Originally developed in Japan in the 1990’s, the Volute Press is presently used in more than 5000 installations around the world, with 300 in the US alone. The PWTech® Volute™ Dewatering Press is a significant upgrade over the standard dewatering screw press technology; we think of it as “Screw Press 2.0.” Specifically, it offers a much more compact size and lower maintenance than the technologies it supersedes.

The key to the process is the “dewatering drum.” This drum can achieve both thickening and pressing (dewatering) of the sludge in a single operation that is significantly more compact and therefore cost effective than similar technologies. The Volute Dewatering Press can take sludge as dilute as 0.1% solids directly from a treatment process, such as an oxidation ditch or clarifier, and produce a dry cake suitable for disposal or further drying. With an efficient system design, the Volute Press is a fully automated system capable of starting up, operating, and shutting down with no operator intervention. Additionally, it eliminates the continuous use of wash water and high-power consumption.

APPLICATIONS

The PWTech Volute Dewatering Press has been installed to dewater a wide range of sludges. It is especially useful with sludge that has a high oil and fat content that would bind filter materials. Here are just a few examples:

- Waste biological sludges (including WAS, fixed film, MBR, aerobic and anaerobic digested)

- Potable water sludges (including alum, ferric, and PAC sludges)

- DAF float from slaughter houses and other agricultural processes

- Oil sludge from machining operations

- Wastes from textile processing

- Food processing and wash-down wastes

PWTech can provide complete dewatering systems, including all related appurtenances such as pumps and conveyors or work with other suppliers to provide an integrated package. In addition, unit operating and alarm outputs for connection to plant PLC/SCADA systems are standard. Several models are available with capacities from 1 to >200 GPM for individual units. Download our product flyer for a list of available model sizes.

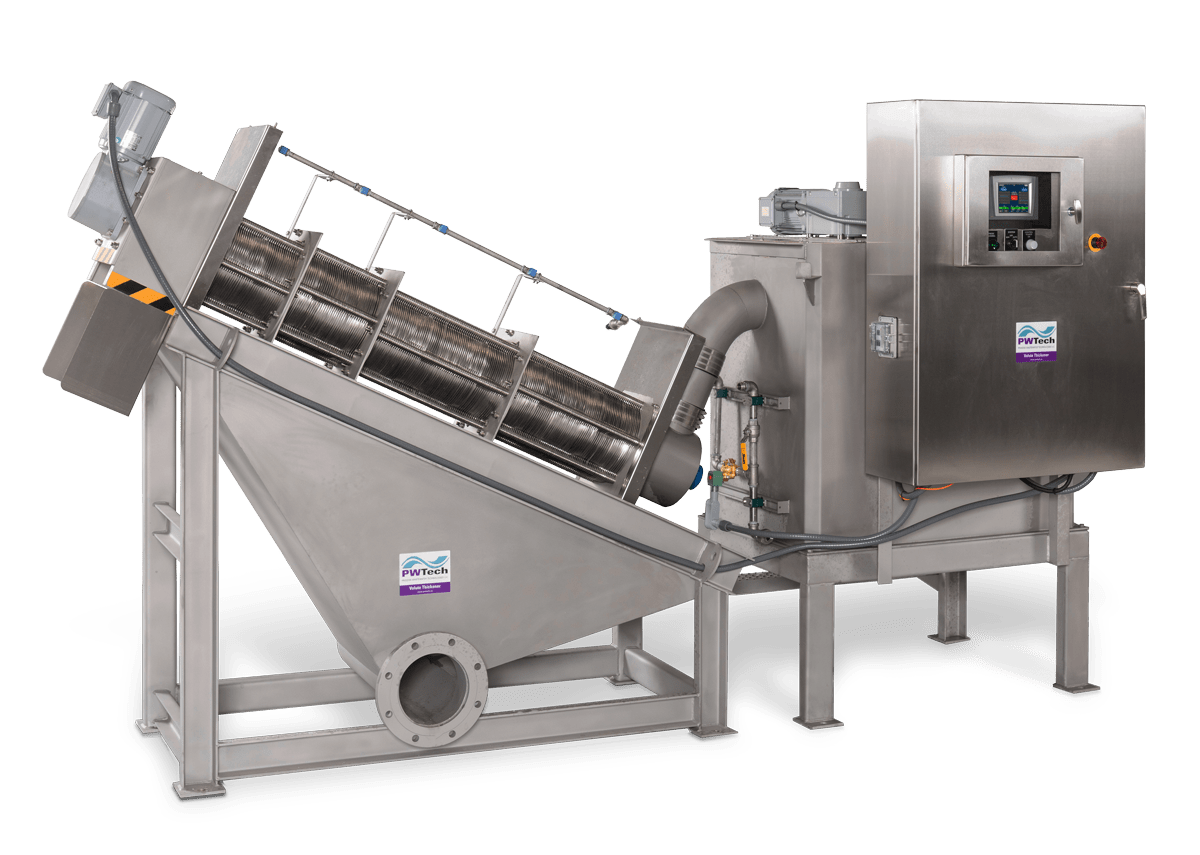

Volute Thickener (treatment plants)

ADVANTAGES

- Delivers 24-hour unattended operation

- Offers more than 99% high solids recovery

- Uses minimal power regardless of the size

- Requires minimal maintenance between overhauls

- Requires zero wash water under normal operation

- Designed with stainless steel, engineered plastics, and “sealed for life” drive motors

Description

The PWTech® Volute Thickener is a fully automated, virtually maintenance-free unit using a modified version of the Volute Press “dewatering drum” to achieve thickening of sludge. It’s an integrated unit that includes a polymer system, feed pump, flocculation tank, and controls.

APPLICATIONS

The Volute Thickener is ideal for concentrating sludge as low as 0.03% to 5% or more to:

- Reduce storage/digester size requirements

- Reduce transport and handling costs

- Reduce other downstream loading requirements on pumping or dewatering

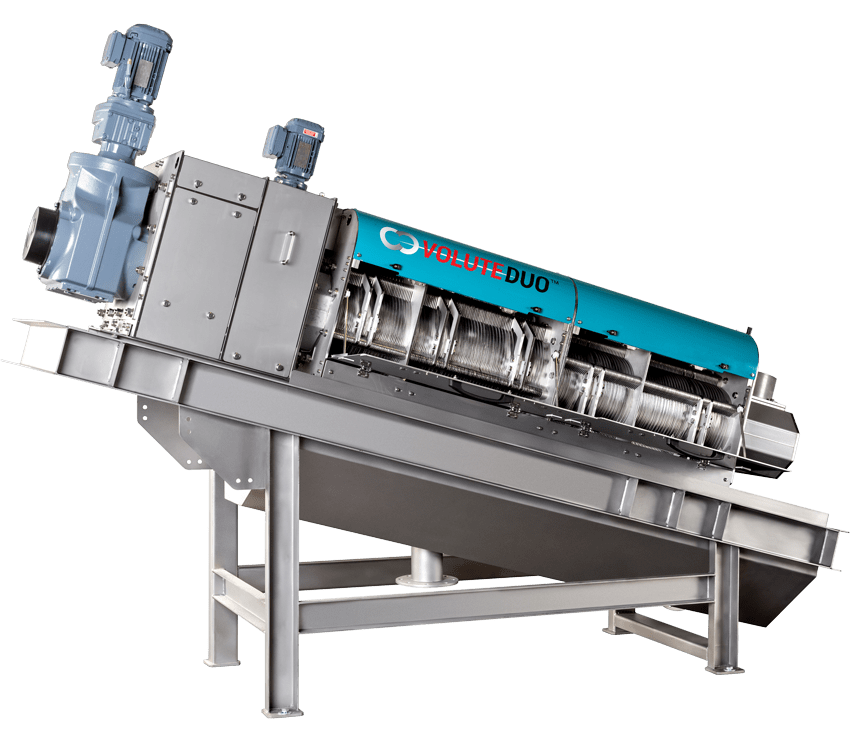

Volute Duo

ADVANTAGES

- Requires minimal maintenance with no brushes, seals or wipers

- Offers the highest dewatering capacity of any available screw press

- Delivers 24-hour unattended operation

- Uses up to 95% less power than other dewatering processes

- Consumes minimal wash water

- Processes feed sludges from <0.2% to >8%

Description

With standard screw press technology, the final cake product needs to be malleable enough to extrude from the end of the screw press (or dewatering drum). When their dewatered, sludges that contain high concentrations of fibrous, inorganic, or adhesive material can form a compacted cake that is too hard to extrude from the screw press. This plugs the press, which makes it difficult to pass solids or it may require lower cake solids performance to allow for continuous operation.

The PWTech® Volute DUO is designed with a smaller footprint than the standard Volute Dewatering Press. It takes the original Volute dewatering drum concept and adapts it for the dewatering of difficult sludges. It utilizes twin counter-rotating screws inside a single drum to break up and move all material for dewatering. This makes it possible for full mechanical dewatering of more difficult sludges without the performance being compromised.

The DUO uses a separate drive mechanism so that the moving rings don’t contact the screws as they move. That prevents wear points on the press, which can result in many years of maintenance-free operation. Since the mechanism is completely enclosed, it minimizes odor and noise.

APPLICATIONS

The Volute Duo can be utilized in virtually all sludge dewatering applications however it is most applicable to applications that would create plugging or binding of more traditional screw press designs.

Such applications include:

- WTP sludge (Alum, Ferric, and Lime sludge)

- Pulp and paper applications

- Raw manure

- Dredging and land remediation applications

- Dewatering of raw primary sludge