Sansep

ADVANTAGES

- Offers a smaller footprint, no above ground facilities and a large flow range

- Requires minimal maintenance

- Designed with patented non-blocking screen technology

- Allows effluent to be UV disinfected

- Efficiently captures solids finer than the screen

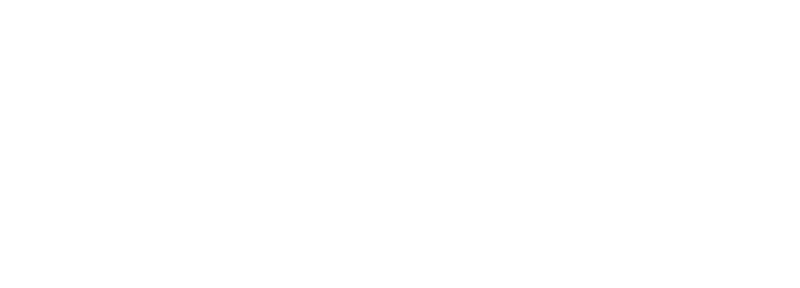

Description

The SanSep provides a much more efficient level of solids removal than other mechanical and static screening devices that are typically used in wet weather excess sanitary flow treatment. Utilizing patented PWTech® technology, the SanSep allows screening of the solids without blocking. It greatly reduces the impact of excess wet weather sanitary flows by removing all visible solids and associated pollutants and returning them directly to the sewer. Download our product flyer for more details.

APPLICATIONS

A single unit treats flows ranging from 0.3 to 40 cfs, while multiple units can be used for even larger flows. Typical loading rates across the whole unit are 150 gpm/ft². With its non-blocking screen, the SanSep operates continuously at its maximum design flow.

A process logic controller with a level sensor within the unit controls this entire process and returns the unit to standby condition between wet-weather sanitary flow events. Thus, operator attendance at sites is not required.

Raked Bar Screen

ADVANTAGES

- Features a horizontal screen configuration

- Ensures both high and low flows are screened with minimum velocities

- Screens entire flow with a perpendicular flow path

- Minimizes jamming and breaking of comb tines

- Offers equal loading across the surface

- Distributes force on cleaning rakes

Description

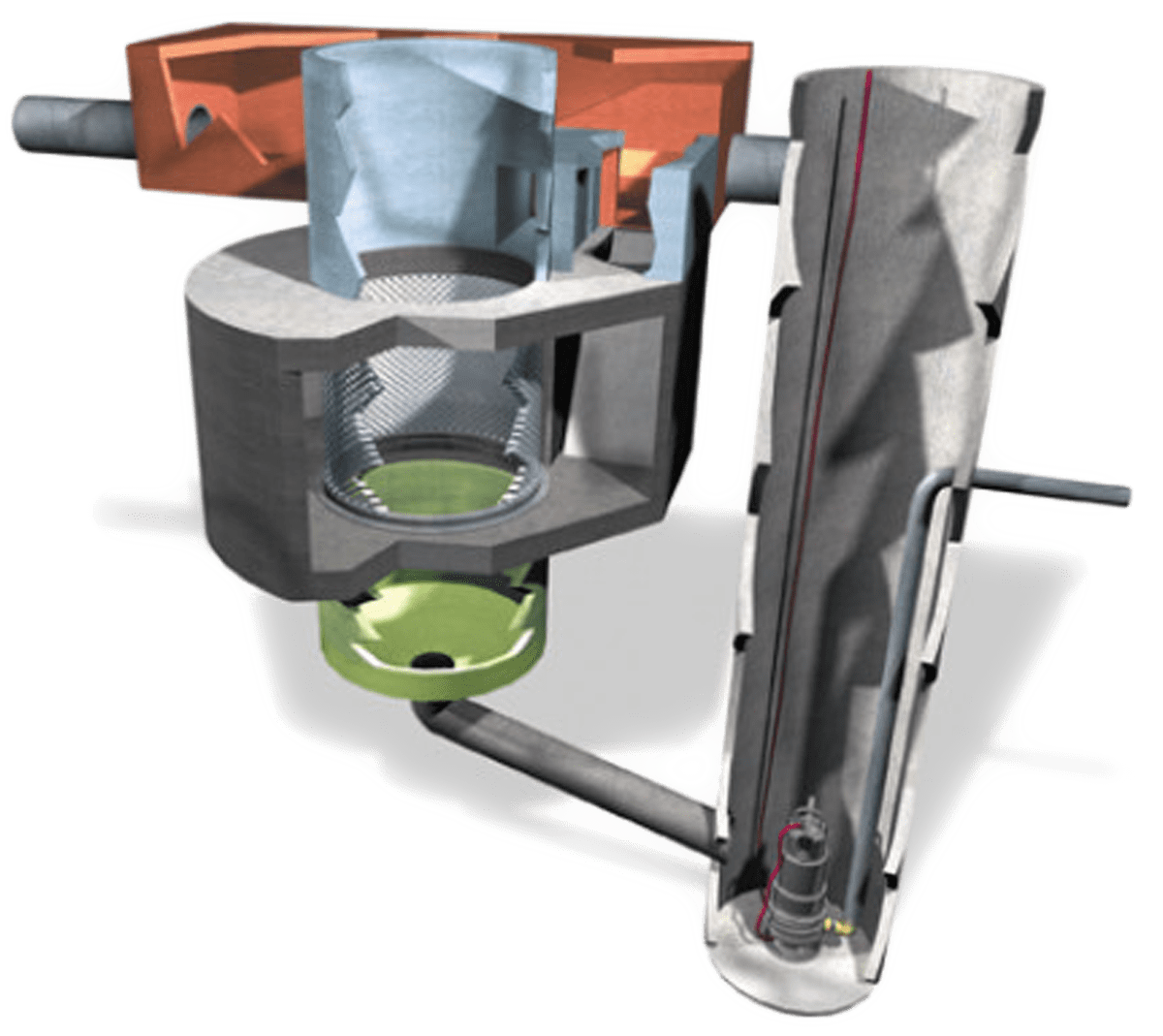

The Raked Bar Screen is an efficient, reliable and cost-effective screening system for large combined sewer overflows (CSOs). It incorporates a horizontal fixed stainless steel bar-rack and a TIVAR* screen comb. The bars are continually raked by the hydraulically driven comb assembly. Maintenance of the Raked Bar Screen is minimal, and can be performed from the top/clean water side of the screen. Download our product flyer for more information on system operation.

Design Criteria

Patented design features that distinguish the performance and reliability of the PWTech® Raked Bar Screen include:

- Recessed release zones at every 2 ft. of screen length

- Modular construction

- Single screen can handle flow rates from 3 to 100 mgd

- 3/16", 1/4", 5/16", 3/8" and 1/2" bar spacings

*TIVAR is the registered trademark of Poly Hi Solidur, Ft. Wayne, Ind.

Cyclone

ADVANTAGES

- Requires minimal maintenance and no external power source

- Installs quickly and easily

- Designed with a self-cleansing aperture screen

- Effectively treats small combined sewer overflows

Description

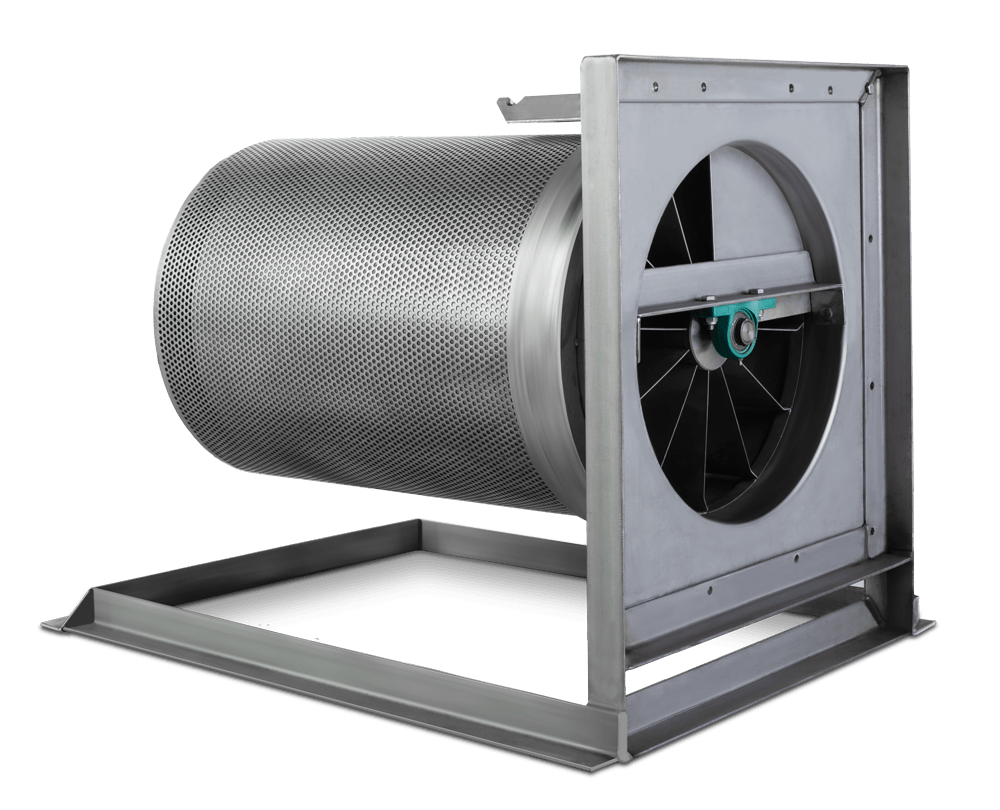

This patented self-powered drum screen is ideal for applications such as storm water tank discharges, pumping station overflows, sewage treatment plant by-passes, and small combined sewer overflows. The Cyclone achieves 100 percent removal of ¼-in. (6-mm) particles for two dimensions. Designed to be virtually maintenance free, the Cyclone has a projected 20-year life. Download the product flyer for more information on how the Cyclone operates.

Construction

Manufactured from 316L or 304L stainless steel, then electro-polished, the Cyclone bolts directly to a chamber wall over a circular outlet, or spans across the CSO chamber from weir wall to chamber wall. The shaft bearings are also stainless steel and are sealed for life. The standard drum unit is 28 in. (710 mm) long with a 20-in. (500-mm) diameter. Whether installed individually or in multiples, the Cyclone can be designed with quick-release fittings and frames for easy removal and access to the CSO chamber.

Design Criteria

Three standard sizes with design flows of 1.77 cfs (1.14 mgd), 3.53 cfs (2.28 mgd), and 5.30 cfs (3.43 mgd).